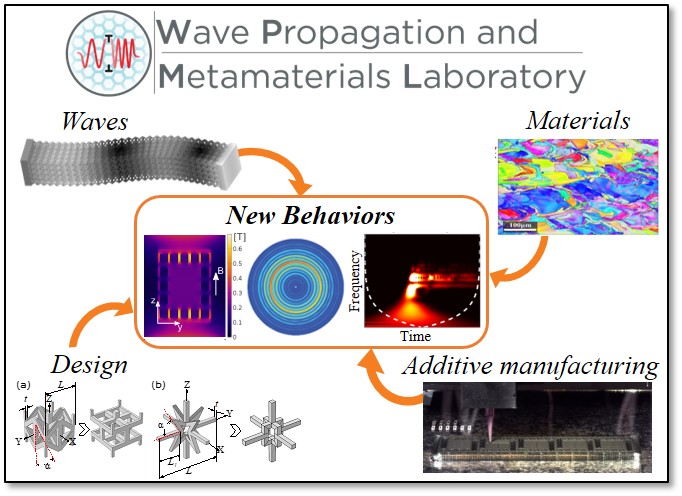

The Wave Propagation and Metamaterials (WPM) Lab is a research team dedicated to uncovering fundamental mechanical relationships between structure and mechanical wave propagation. We study how the structure at different length scales lead to new ways to control how mechanical waves propagate in materials.

We seek fundamental mechanics-based discovery yet we are driven by critical applications. We strive to understand how the concepts we study can be applied in real materials and structures. We place an emphasis on fabrication and experimental realization, as well as realistic material platforms. Our group has two main focus areas:

Phononic Metamaterials: Our goal is to design new materials and structures that can control mechanical waves in unprecedented ways. We take a holistic modeling-experimental approach, integrating simple physics-based analytical models, high-fidelity simulations, advanced manufacturing, and experimental wave mechanics. Our current thrusts include:

- Multifunctional Lattices

- 3D Printed Architected Metamaterials

- Stimuli-Responsive Metastructures

- Radial Phononic Materials

- Nonlinear Phononic Materials

Ultrasonic NDE: The main goal of this aspect of our research is to understand the relationship between microstructure and the ultrasonic response, in order to develop new methods of NDE. Our approach is primarily experimental, integrating advanced ultrasonic measurements with comprehensive micro-structural analysis and mechanical testing. Current thrusts include:

Motivation: The “grand challenge” for materials design is to satisfy multiple and conflicting design requirements. Energy infrastructure, especially in remote and extreme environments e.g. offshore wind turbines and nuclear reactors, requires components to operate effectively over long time periods and prevent catastrophic failures. Structural materials in e.g. aviation must be lightweight but high in strength, stiff while dampening out harmful vibrations, and survive damaging impact events. Specifically, the ability to engineer desirable stress wave behaviors in structural materials will result in safer and more efficiently operating structural components. Addressing similar challenges on smaller scales, e.g. for sensors and other MEMS devices, can advance biomedical imaging capabilities and ultrasonic sensing techniques.